Introduction

- Focus is on oil testing only

- Proper periodicity of tests is not followed

- Tests do not cover all common failure modes

- Lack of awareness of the standards to be followed

- Lack of clarity on how to interpret the test data

- Lack of awareness about the benefits of the individual tests

Concept:

Oil testing and DGA are powerful tools that assess oil degradation, heating, arcing and insulation oxidation. They should always be the starting point of any transformer health monitoring program. However, they are unable to identify many issues as conductor defects, mechanical deformation, short circuits, localized discharges, etc. The addition of other tests to the program can greatly enhance its effectiveness. In the ensuing section, we will address the shortcomings raised earlier.

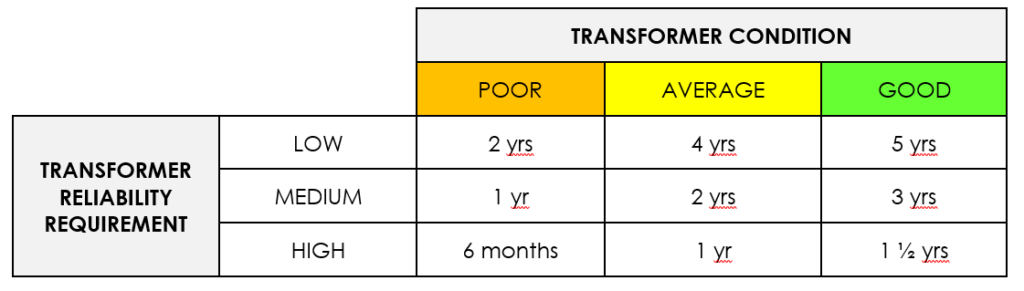

How often should we test transformers?

This is best addressed in the ANSI-NETA Maintenance Testing Specifications 2019 standard. Herein, it is required that the owner/operator of the transformer rate the importance of the transformer as LOW, MEDIUM or HIGH. This rating is based on its effect on plant operation, downtime costs, safety implications, etc. Subsequently, the appropriate tests should be performed and the results evaluated. These results should be categorized as POOR, AVERAGE or GOOD. Finally, these results should be compared to Table 1 to decide when each transformer should be tested next.

Table 1: ANSI-NETA MTS-2019 - Recommended time for next test

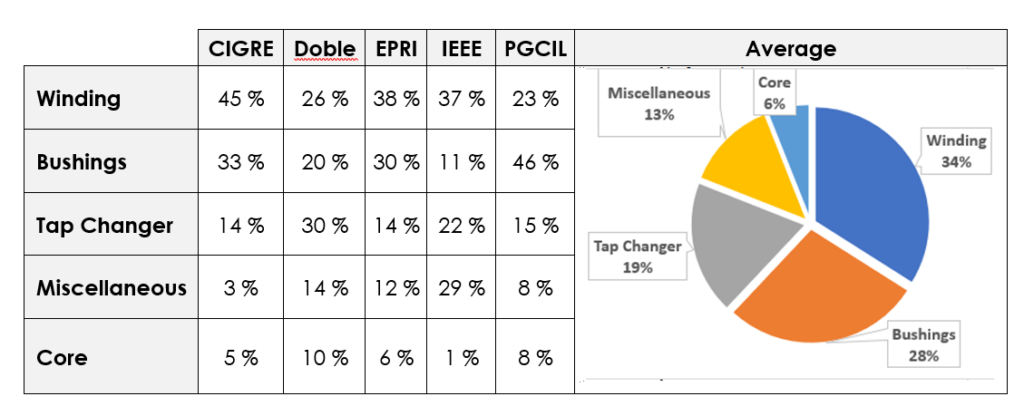

What are the most common failures in transformers?

It is difficult to make a generalized statement about the failures, as different organizations have had different experiences. However, a compilation of statistics from across global experiences does show that windings tend to fail the most, while core defects are the rarest (see Table 2).

Table 2: Most common failures for transformers

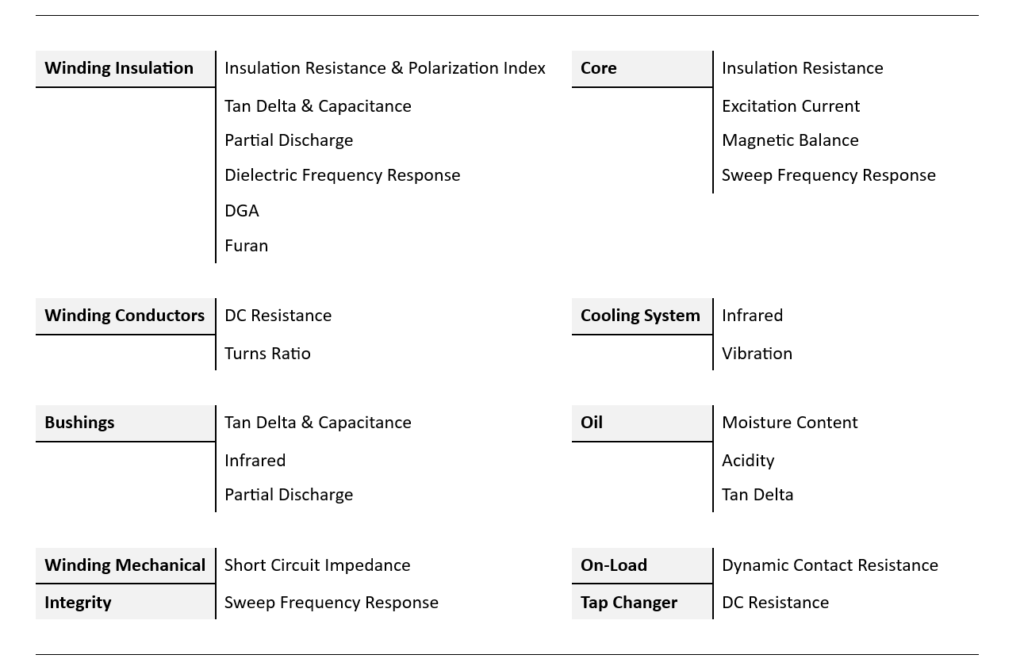

What are the tests that should be performed to identify such incipient defects?

The basic tenet for any diagnostic testing is that there should be at least one test for each failure mode, and two tests for the most common failure modes. The reason for this is that every test can be misleading from time to time, but the cross confirmation from two different is most reliable. The following standards are excellent references for the tests to be performed:

- IEEE C57.152-2013

- ANSI-NETA MTS 2019

- CIGRE 887-2022

In addition to these, there are numerous standards which specify how each test is to be performed and interpreted. Listing all of them is beyond the purview of this article. However, Table 3 shows the various tests that can be performed in to identify all failure modes (CIGRE 87-2022 goes into great depth in this regard).

Table 3: Tests for detecting various failure modes

Guidelines for interpretation of the common tests

Electrical tests can be broadly sorted into routine tests that can be performed by most electrical personnel, and specialized tests that require extensive training and experience. The latter can be the subject of a separate paper. However, guidelines for interpretation of the common tests are provided below:

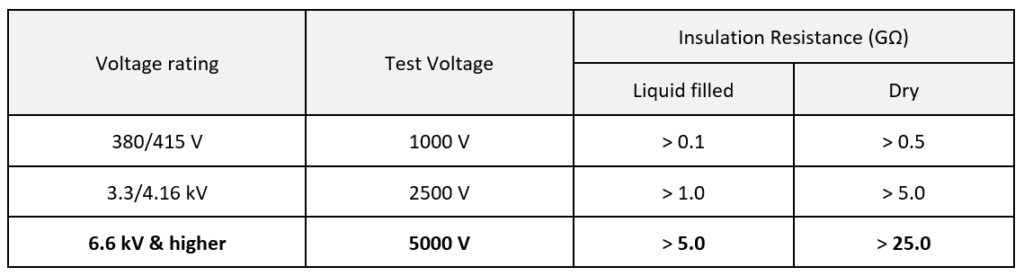

Insulation Resistance – determine if it is safe to energize the transformer

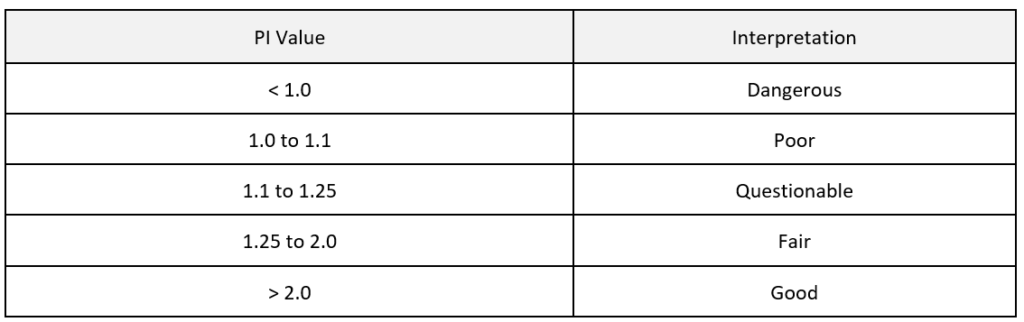

Polarization Index – determine if it is safe to energize the transformer

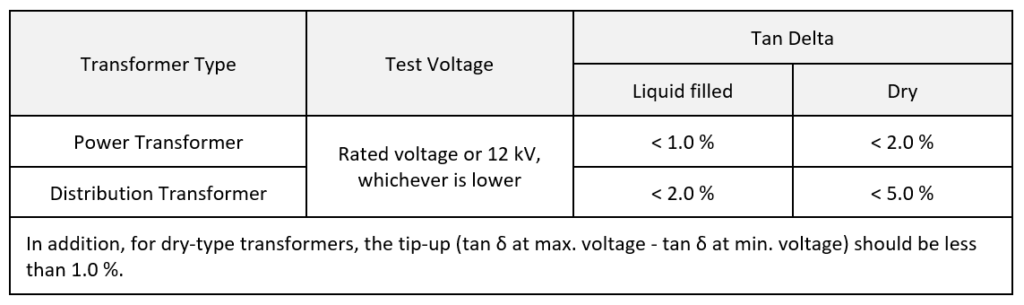

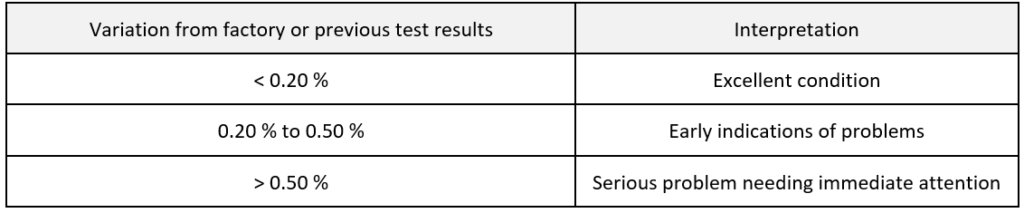

Tan Delta & Capacitance – detection of moisture ingress and insulation degradation

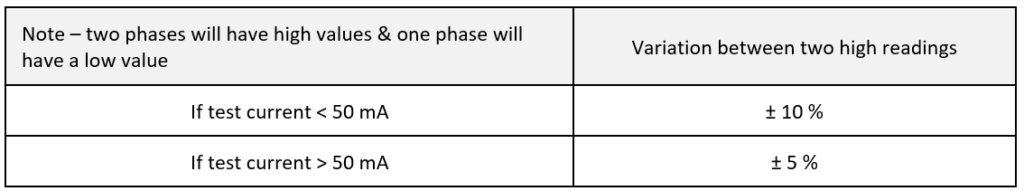

Winding Resistance – detection of loose connections, broken strands and bad contacts

Variation between phases | < 2 % |

Variation from factory test values | < 5 % |

Turns Ratio – detection of shorted turns

Excitation Current – detection of unequal turns or core defects

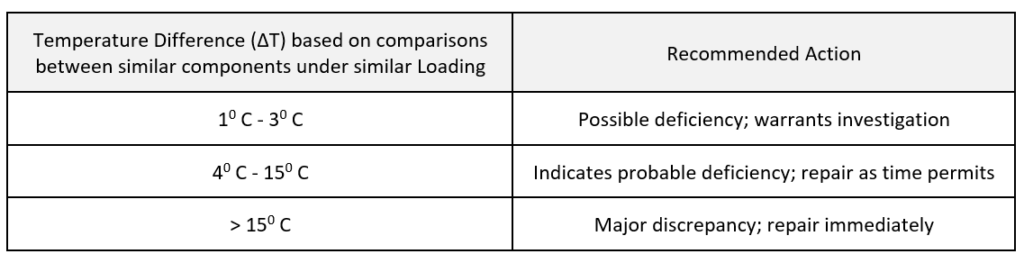

Thermography – detection of overheated components and blocked cooling circuits

Benefits of the specialized tests

Partial Discharge Test – This can detect various localized defects in the insulation that may not be detectable by any other tests. It can also determine the type of defect, based on which the correct maintenance activity can be planned. In some cases, the acoustic partial discharge test can also determine the approximate location of the defect.

Dielectric Frequency Response Test – This test can determine the extent of moisture within the paper insulation, which is not possible from oil sample tests. It is also far more sensitive to moisture ingress as compared to the tan delta test. Lastly, it can determine the conductivity of the oil, which helps decide if oil needs to be replaced or reclaimed.

Sweep Frequency Response Test – This test helps determine the integrity of the core, as well as detection of other issues such as winding deformation, hoop buckling, clamping structure problems, etc. The test is purely a comparative tests, and hence baseline data is critical.

Frequency Response of Stray Losses – This test can detect short circuits of parallel strands and local over-heating, often caused due to excessive eddy currents & winding deformation.

Dynamic Resistance Measurement – This test can detect defects in on-load tap changers without having to do any internal inspection.

Furan Analysis – This can determine if the paper insulation has reached the end of its reliable life.

Conclusions

Transformer testing if performed systematically and correctly can greatly enhance their reliability. Strategies need to be customized depending upon age, criticality, failure history, voltage ratings, etc. While not every transformer needs exhaustive diagnostics, the reliance on oil testing and insulation resistance alone will not suffice to meet today’s increased reliability expectations. Systematic application of modern techniques along with a thorough knowledge of their concepts are the best way forward to meet these goals. At DIATECH, we provide such professional services using the latest technologies. For more information, contact us or request a quote.