Home > Case Studies

Case Studies

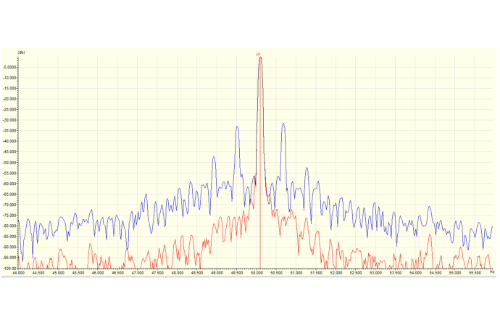

This motor was running smoothly with overall vibration under 2.0 mm/sec, no temperature rise or abnormal noise. MotoCARE® testing indicated that the motor had suffered significant rotor bar damage. On opening, it was observed that 8 rotor bars were broken.

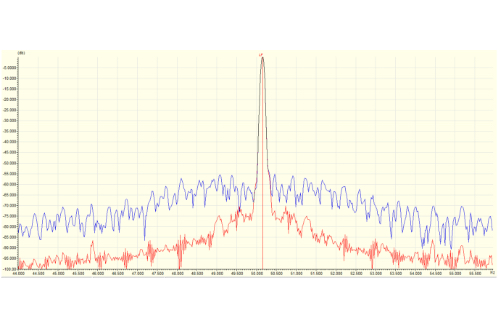

Routine testing with MotoCARE® revealed these faults. As client could not take a shutdown, we trended this motor till the fault amplitude worsened. In the meanwhile, the client arranged the spare stator and got it replaced with a few hours’ shutdown. Had the motor not been tested, it would have failed shortly and lead a long breakdown of the entire plant.

MotoCARE® predicted a severe rotor fault, along with stator core damage. No action was taken. The rotor failed within a month. The fault was so severe that some of the rotor copper melted & sprayed on to the stator, damaging it too. The plant was shut down for nearly a month till the motor could be repaired.

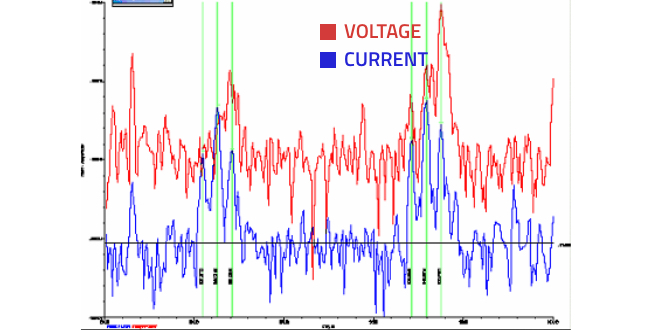

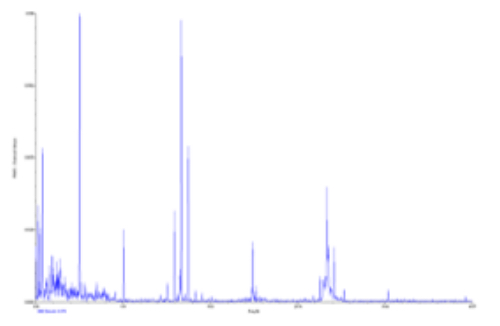

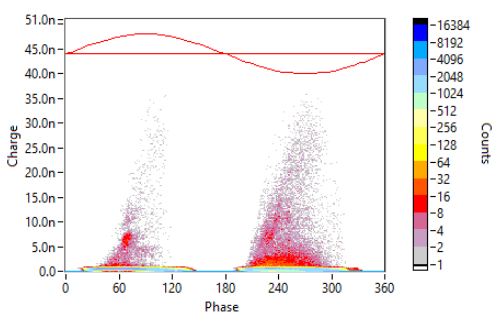

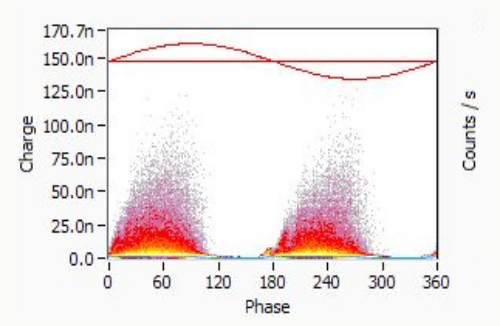

GenCARE testing during a shutdown revealed extremely high partial discharge for one phase. The patterns were typical of end-winding PD. Physical inspection showed that corona had eaten away the end winding insulation of R Phase & this would have failed shortly. Remedial action was taken and the generator has since been in service for over 9 years.

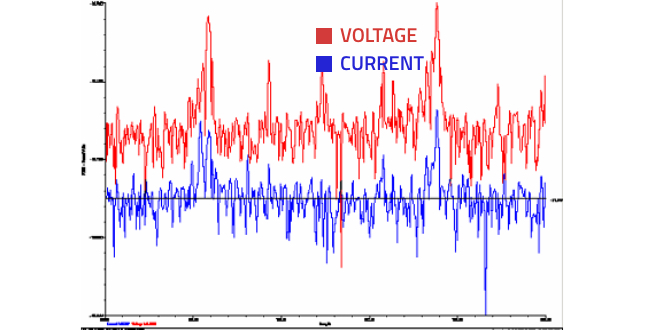

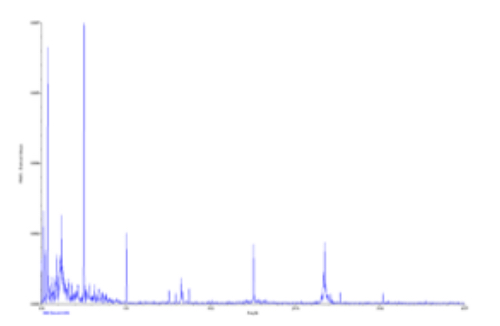

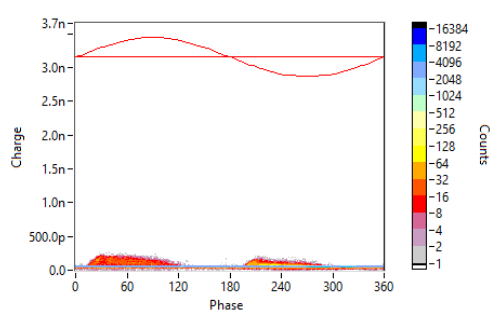

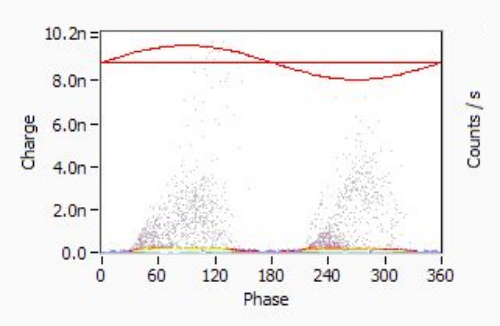

Two identical generators have been in operation for over 15 years now. GenCARE testing showed that one of them has severe internal contamination. Physical inspection revealed that severe oil & carbon ingress had occurred and this had drastically degraded the insulation. Remedial action was taken & the generator now runs fine.

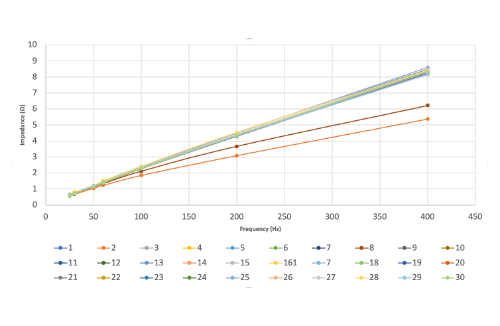

Brand new rotor field coils were being fitted based on manufacturer’s recommendations. New coils had been procured from the manufacturer itself. MotoCARE® testing identified that two of these coils were defective, due to inter-turn shorts. Had these coils been installed, they would have led to hunting during operation & premature failure.